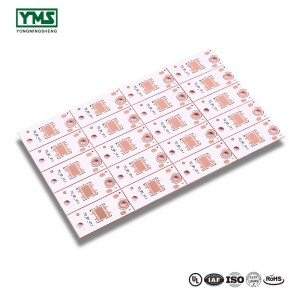

Factory making Assurance 0.2mm Thickness Double Side Flex Led Lighting Fpcb Board

Our personnel are always in the spirit of “continuous improvement and excellence”, and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer’s rely on for Factory making Assurance 0.2mm Thickness Double Side Flex Led Lighting Fpcb Board, The mission of our enterprise is always to offer the very best quality merchandise with best price. We are seeking ahead to doing enterprise with you!

Our personnel are always in the spirit of “continuous improvement and excellence”, and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer’s rely on for Black Coverlay Led Fpcb, Double Side Pcb Fpcb Led Flex Pcb Board, White Coverlay Led Strip White 2mm Thin Flexible Pcb, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our solutions and the processes to fulfill your needs.

FPC has many benefits, including:

• save space. Flexible PCB designs require only about 10% of the space and weight of ordinary circuit board components, providing greater freedom of installation and packaging. The inherent flexibility also allows for more compact bending capabilities.

• enhancements. Flexible printed circuit boards are compatible with almost any type of connector or component and can be used with options such as ZIP connectors. They also perform well at extreme temperatures and have excellent radiation and chemical resistance.

• highest reliability. Flexible printed circuit boards require fewer interconnections, which in turn require fewer contact presses, connectors, and solder joints. In short, flexible PCB boards do not contain many potential fault sources, thus increasing their reliability.

• cost savings. The cost savings of flexible PCB include reduced material and packaging requirements, lower component replacement costs and assembly errors that may require maintenance.

You May Like:

1、PCB copper coating experience

2、FPC flexible circuit board testing methods and standards

3、Discussion on the structure hierarchy of flexible circuit board