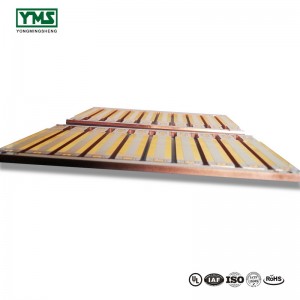

High Quality Bare Copper Pcb Circuit Board,6.0mm 2l Frequency Metal Board Copper Electronic Pcb,Shenzhen Pcb Circuit Boards

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Quality Bare Copper Pcb Circuit Board,6.0mm 2l Frequency Metal Board Copper Electronic Pcb,Shenzhen Pcb Circuit Boards, Hope we can easily generate a more glorious potential along with you by means of our endeavours within the long run.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Copper Pcb, Frequency Pcb, Speed Pcb, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our items or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences