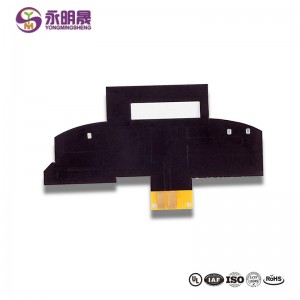

PriceList for China OEM ODM FPC Flexible Cable Flex PCB

We stay with the basic principle of “quality initially, services first, steady improvement and innovation to fulfill the customers” for your management and “zero defect, zero complaints” as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for PriceList for China OEM ODM FPC Flexible Cable Flex PCB, We are looking forward to receiving your enquiries soon.

We stay with the basic principle of “quality initially, services first, steady improvement and innovation to fulfill the customers” for your management and “zero defect, zero complaints” as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for China FPC PCB, flex pcb, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

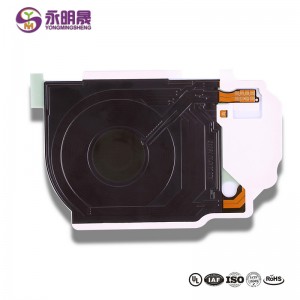

What is a FPC?

Flexible Printed Circuit (FPC) is a technology developed by the United States in the 1970s to develop space rocket technology, which is based on polyester film and polyimide as base material made of a kind of with high reliability, excellent rendition of flexible printed circuit. Through embedding circuit design in the flexible thin plastic sheet make the pile embedded in narrow and limited space a large number of precision components, so that a flexible printed circuit is formed.

This kind of circuit can be bent and folded at will, which is light in weight, small in volume, good in heat dissipation and easy to install.

Different Copper Foils Used in Flex Circuit

[Process Description]

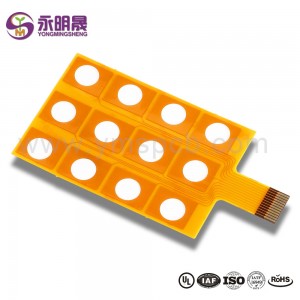

The copper foil used in the FPC depends on the applications.

[General Procedure]

Copper foil material used in normal PCB has two types, electrodeposited copper foil and rolled copper foil, and used in different applications.Rolled copper foil is used in dynamic flexible production for its compactness and flexure resistance.

Electrodeposited copper foil is used in non-dynamic flexure applications Rolled copper foil manufacturing process will create much stress and then need annealing.After annealing, rolled copper foil has suitable grain structure to prevent crack propagation.That’s why it has flexure resistance.

People also ask: