Professional Factory for China FPC/FPCA, FPCBA, flexible PCB, flex PCB, rigid-flex PCB/HDI flex PCB/FPC, PCB/flex PCB laminating service

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Professional Factory for China FPC/FPCA, FPCBA, flexible PCB, flex PCB, rigid-flex PCB/HDI flex PCB/FPC, PCB/flex PCB laminating service, We sincerely welcome overseas customers to consult for the long-term cooperation and the mutual development.We strongly believe that we can do better and better.

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for China Rigid-flexibile FPC/FPCA, flexible-rigid FPCA/FPC, We always insist on the management tenet of “Quality is first, Technology is basis, Honesty and Innovation”.We’ve been able to develop new items continuously to a higher level to satisfy different needs of customers.

What is HDI PCB?

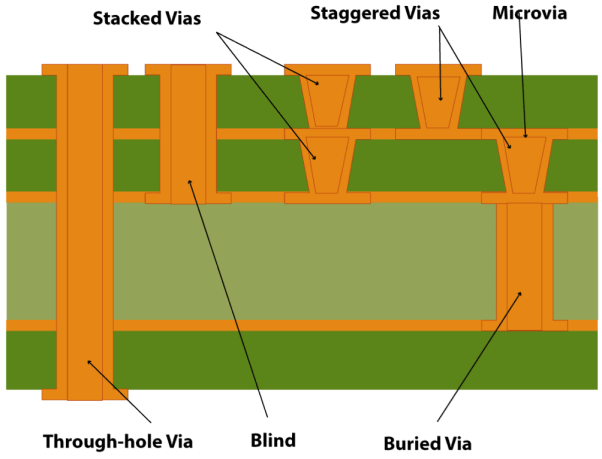

HDI PCB: High density interconnect PCB, are a way of making more room on your printed circuit board to make them more efficient and allow for faster transmission. It’s relatively easy for most enterprising companies that are using printed circuit boards to see how this can benefit them.

Advantages of HDI PCB

The most common reason for using HDI technology is a significant increase in packaging density. The space obtained by finer track structures is available for components. Besides, overall space requirements are reduced will result in smaller board sizes and fewer layers.

Usually FPGA or BGA are available with 1mm or less spacing. HDI technology makes routing and connection easy, especially when routing between pins.

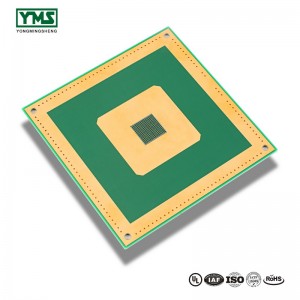

YMS HDI PCB manufacturing capabilities:

| YMS HDI PCB manufacturing capabilities overview | |

| Feature | capabilities |

| Layer Count | 4-60L |

| Available HDI PCB Technology | 1+N+1 |

| 2+N+2 | |

| 3+N+3 | |

| 4+N+4 | |

| 5+N+5 | |

| Any layer | |

| Thickness | 0.3mm-6mm |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) |

| BGA PITCH | 0.35mm |

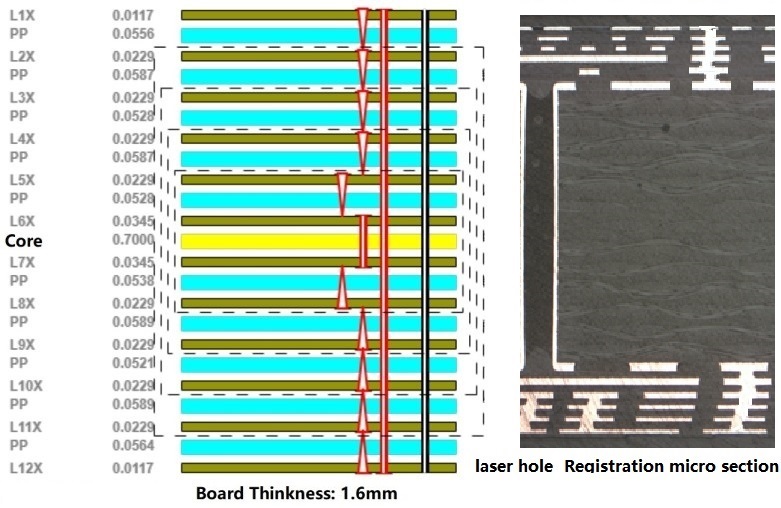

| Min laser Drilled Size | 0.075mm(3nil) |

| Min mechanical Drilled Size | 0.15mm(6mil) |

| Aspect Ratio for laser hole | 0.9:1 |

| Aspect Ratio for through hole | 16:1 |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over |

| Copper filled, silver filled | |

| Laser via copper plated shut | |

| Registration | ±4mil |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. |

You May Like:

1、How to identify gold on a pcb

4、The main causes of PCB board deformation and rupture