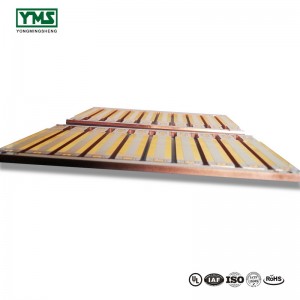

High Quality for Smt Pcbpcba And Electronic Components Printed Circuit Assembly

Our primary intention will be to provide our clientele a serious and responsible small business relationship, giving personalized attention to all of them for High Quality for Smt Pcbpcba And Electronic Components Printed Circuit Assembly, Our company has been devoting that “customer first” and committed to helping clients expand their organization, so that they become the Big Boss !

Our primary intention will be to provide our clientele a serious and responsible small business relationship, giving personalized attention to all of them for Electronic Components, Pcb Assembly, Smt Pcbpcba, We believe with our consistently excellent service you can get the best performance and cost least solutions from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences