I-Ceramic PCB enye kunye namacala amabini iiseramics I-PCB yenza i-Ceramic Substrates | YMS PCB

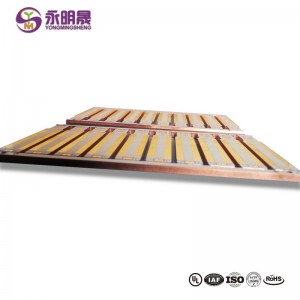

I-PCB yeCeramic: ibhodi yesekethe ye-ceramic substrate

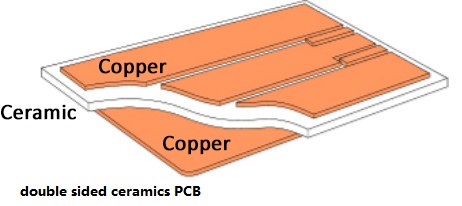

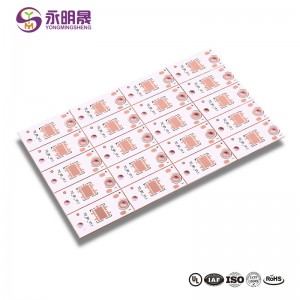

I-Ceramic Substrate ichaza ibhodi yenkqubo eyodwa apho ifoyile ye-aluminiyam yobhedu ibambelele ngokuthe tye kwindawo ephezulu (icala elilodwa okanye icala elimbini) le-alumina (Al2O3) okanye i-aluminiyam ekhaphukhaphu ye-nitride (AlN) ye-ceramic substrate kubushushu. Xa kuthelekiswa nomgangatho we-FR-4 okanye ubunzima obuncinane be-aluminium substrate, i-substrate ehlanganisiweyo ye-ultra-ebhityileyo eyenziweyo inokusebenza kakuhle kokufakwa kombane, ukusebenza kakuhle kwe-thermal, i-solderability ethambileyo ekhethekileyo kunye nokuqina kwebhondi ephezulu, kwaye ingakrolwa imizobo emininzi efana nePCB, fantastic ekhoyo lugging isakhono. Ilungele izinto ezinobushushu obuphezulu (ukukhanya okuphezulu kwe-LED, amandla elanga), kunye nokumelana nemo yezulu ephezulu ikhethwayo kwisetingi zangaphandle ezirhabaxa. Intshayelelo yeTekhnoloji yeBhodi yeSekethe yeCeramic

Kutheni usebenzisa izinto zeeramics ukuvelisa iibhodi zeesekethe? Iibhodi zeesekethe zeCeramic zenziwe ngeekeramics ze-elektroniki kwaye zingenziwa ngeendlela ezahlukeneyo. Iimpawu zokumelana nobushushu obuphezulu kunye nokufakelwa kombane ophakamileyo weebhodi zeesekethe ze-ceramic zizona zibalaseleyo. Izibonelelo zedielectric ephantsi rhoqo kunye nokulahleka kwe-dielectric, ukuhanjiswa okuphezulu kwe-thermal, ukuzinza okuhle kweekhemikhali, kunye ne-coefficient yokwandiswa kwe-thermal efanayo kumacandelo nazo zibalulekile. Ukuveliswa kweebhodi zeesekethe ze-ceramic kuya kusebenzisa iteknoloji ye-LAM, iteknoloji ye-laser ye-activation metallization. Zisetyenziswa kwintsimi ye-LED, iimodyuli ze-semiconductor yamandla aphezulu, iifriji ze-semiconductor, izifudumezi zombane, iisekethe zokulawula amandla, iisekethe ze-hybrid zamandla, izixhobo zamandla ezihlakaniphile, ukuhanjiswa kwamandla aphezulu, ukuhanjiswa kombane, ii-elektroniki zemoto, unxibelelwano, i-aerospace, kunye nezixhobo ze-elektroniki zomkhosi.

Izinto eziluncedo zeCeramic PCB

Ngokungafaniyo ne-FR-4 yemveli, izinto ze-ceramic zinomgangatho ophezulu wokusebenza kunye nokusebenza kombane, zine-conductivity ephezulu ye-thermal, ukuzinza kweekhemikhali, ukuzinza okuhle kakhulu kwe-thermal, kunye nezinye iipropati ezingenayo i-substrates ye-organic. Yimpahla entsha yokupakisha efanelekileyo yokuveliswa kweesekethe ezinkulu ezidibeneyo kunye neemodyuli zamandla ze-elektroniki.

Iinzuzo eziphambili:

I-thermal conductivity ephezulu.

Okungakumbi kuhambelana ne-coefficient yokwandiswa kwe-thermal.

Ibhodi yesekethe eyomelele kwaye isezantsi yentsimbi ye-alumina ceramic.

I-solderability ye-substrate ilungile, kwaye ubushushu bokusetyenziswa buphezulu.

Ukugquma kakuhle.

Ilahleko yesantya esiphezulu esisezantsi.

Udibaniso olunoxinano oluphezulu lunokwenzeka.

Ayinazithako zezinto eziphilayo, ayixhathisi kwimitha ye-cosmic, inokuthembeka okuphezulu kwi-aerospace, kwaye inobomi obude benkonzo.

Uluhlu lobhedu aluqukethe i-oxide layer kwaye ingasetyenziselwa ixesha elide kwindawo yokunciphisa. IiPCB zeCeramic zinokuba luncedo kwaye zisebenze kakuhle kwiibhodi zesekethe eziprintiweyo kwezi kunye namanye amashishini amaninzi, kuxhomekeke kuyilo lwakho kunye neemfuno zokuvelisa.

I-Ceramic PCB luhlobo lobushushu oluqhuba umgubo we-ceramic kunye ne-organic binder, kunye ne-heat conduction organic ceramic PCB ilungiswe kwi-thermal conductivity ye-9-20W / m. Ngamanye amazwi, i-ceramic PCB yibhodi yesekethe eprintiweyo enesiseko se-ceramic imathiriyeli, enezixhobo zokuqhuba ezishushu kakhulu ezifana ne-alumina, i-aluminium nitride, kunye ne-beryllium oxide, enokwenza isiphumo esikhawulezayo sokuhambisa ubushushu kude neendawo ezishushu kunye nokulahla. phezu komhlaba wonke. Ngaphezu koko, i-ceramic PCB yenziwe ngetekhnoloji ye-LAM, eyitekhnoloji ye-laser yokuvula i-metalization ekhawulezayo. Ke i-ceramic PCB iguquguquka kakhulu enokuthi yenzeke kuyo yonke ibhodi yesekethe eprintiweyo kunye nolwakhiwo oluncinci olunomsebenzi owongeziweyo.

Ngaphandle kwe- MCPCB , ukuba ufuna ukusebenzisa i-PCB kuxinzelelo oluphezulu, ukugquma okuphezulu, ukuphindaphindeka okuphezulu, ubushushu obuphezulu, kunye nokuthembeka okuphezulu kunye neemveliso zombane ezincinci, ke iCeramic PCB iya kuba lolona khetho lwakho lungcono.

Kutheni iCeramic PCB inokusebenza okugqwesileyo? Unokuba nombono omfutshane kwisakhiwo sayo esisisiseko kwaye uya kuqonda.

- 96% okanye 98% Alumina (Al2O3), Aluminium Nitride (ALN), okanye Beryllium Oxide (BeO)

- Izinto zokuqhuba: Kwitekhnoloji yefilimu ebhityileyo, engqindilili, iya kuba yisilivere yepaladium (AgPd), igolide yeplaladium (AuPd); Kwi-DCB (i-Direct Copper Bonded) iyakuba lubhedu kuphela

- Ubushushu besicelo: -55~850C

- Ixabiso le-Thermal conductivity: 24W~28W/mK (Al2O3); I-150W ~ 240W / mK ye-ALN, i-220 ~ 250W / mK ye-BeO;

- Amandla oxinzelelo aphezulu:>7,000 N/cm2

- Ukuqhekeka kweVoltage (KV/mm): 15/20/28 ye-0.25mm/0.63mm/1.0mm ngokulandelelanayo

- I-Thermal Expansion conefficient(ppm/K): 7.4 (ngaphantsi kwe-50~200C)

Iindidi ze-ceramic PCBs

1. Ubushushu obuphezulu be-ceramic PCB

2. Ubushushu obuphantsi be-ceramic PCB

3.Ifilimu etyebileyo ye-ceramic PCB

Ubunakho bokwenza i-YMS Ceramic PCB:

| YMS Ceramic PCB ukwenza amagqabantshintshi ngezakhono | ||

| Uphawu | amandla | |

| Uluhlu Lomaleko | 1-2L | |

| Izinto eziphathekayo kunye nokutyeba | Al203: 0.15, 0.38,0.5,0.635,1.0,1.5,2.0mm njl. | |

| ISONO: 0.25,0.38,0.5,1.0mm njl. | ||

| I-AIN: 0.15, 0.25,0.38,0.5,1.0mm njl. | ||

| I-Thermal conductivity | Al203: Min. 24 W/mk ukuya kuthi ga kwi-30W/mk | |

| ISONO: Min. 85 W/mk ukuya kuthi ga kwi-100W/mk | ||

| AIN: Min. 150 W / mk ukuya kwi-320 W / mk | ||

| Al2O3 | I-Al2O3 inokukhanya okungcono kokubonakala-iyenza ifanele iimveliso ze-LED. | |

| ISONO | I-SiN ine-CTE ephantsi kakhulu. Idityaniswe ne-high Rapture Strength inokumelana nokutshatyalaliswa kwe-thermal. | |

| AlN | I-AlN ine-Thermal Conductivity ephezulu-iyenza ifaneleke kwizicelo zamandla aphezulu kakhulu ezifuna eyona substrate ye-thermal. | |

| Ukutyeba kweBhodi | 0.25mm-3.0mm | |

| Ukutyeba ubhedu | 0.5-10OZ | |

| Ubuncinci bomgca ububanzi kunye nendawo | 0.075mm/0.075mm(3mil/3mil) | |

| Ezikhethekileyo | I-Countersink, i-Counterbore yokumba. Njl. | |

| Ubuncinci boMatshini ogujiweyo | 0.15mm (6mil) | |

| Imathiriyeli yomqhubi: | Kwitekhnoloji yefilimu ecekethekileyo, engqindilili, iya kuba yisilivere yepalladium (AgPd), igolide plladium (AuPd), iPlatinam ye-DCB (i-Direct Copper Bonded) iya kuba lubhedu kuphela. | |

| Umphezulu Gqiba | I-HASL, i-HASL yasimahla, i-ENIG, ukuntywila kwi-Tin, i-OSP, iSilver yokuntywila, iFinger Finger, i-Electroplating Hard Hard, i-OSP ekhethiweyo, ENEPIG.etc. | |

| Solder Vuvu | Luhlaza, Bomvu, Mthubi, Luhlaza, Mhlophe, Mnyama, Mfusa, Matte Mnyama, Matte luhlaza njl njl. | |

| ikhazimlisiwe | Ra <0.1 um | |

| lapped | Ra <0.4 um | |

Funda ngakumbi malunga neemveliso zeYMS

Funda ngakumbi iindaba