Double sided PCB standard pcb Countersink manufacturers | YMSPCB

Printed Circuit Board Introduction

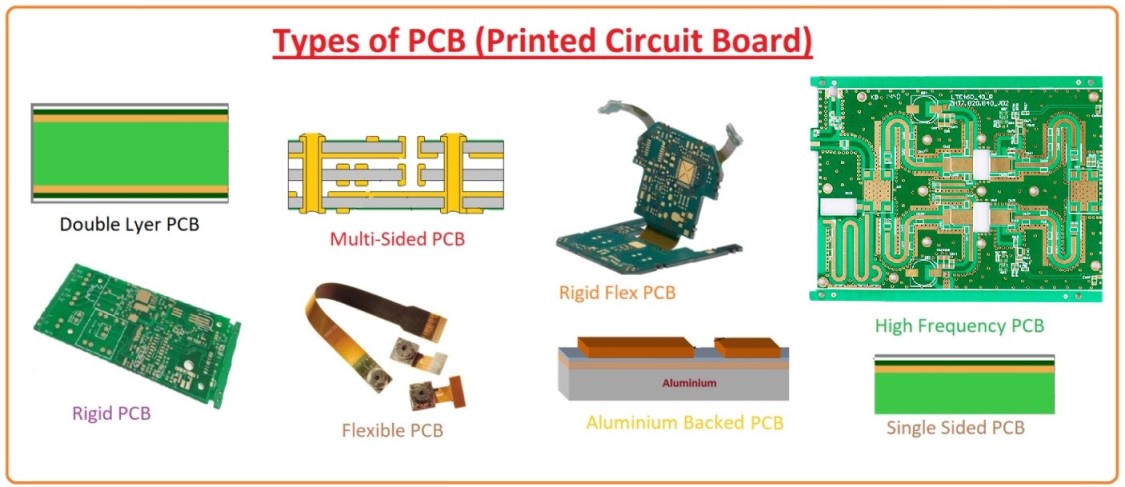

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

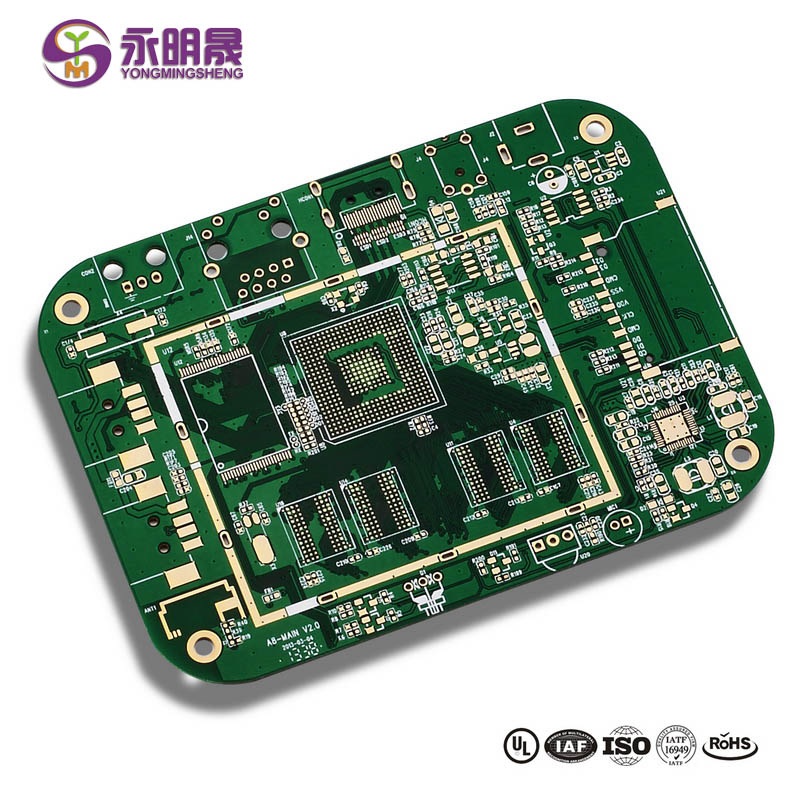

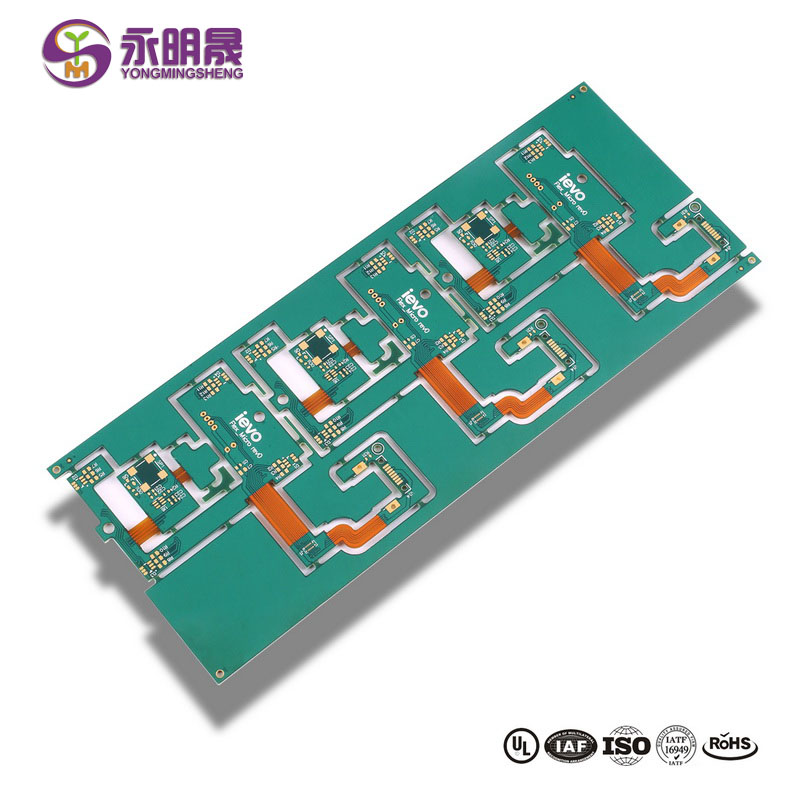

Double-sided circuit boards are a little bit more complex than single sided PCB. These boards contain just a single layer of the base substrate. However, they contain conductive layers on each side. They use copper as a conductive material. Let’s dive deeper inside double sided PCB to learn more!

The Structure and Materials of Double Sided PCB

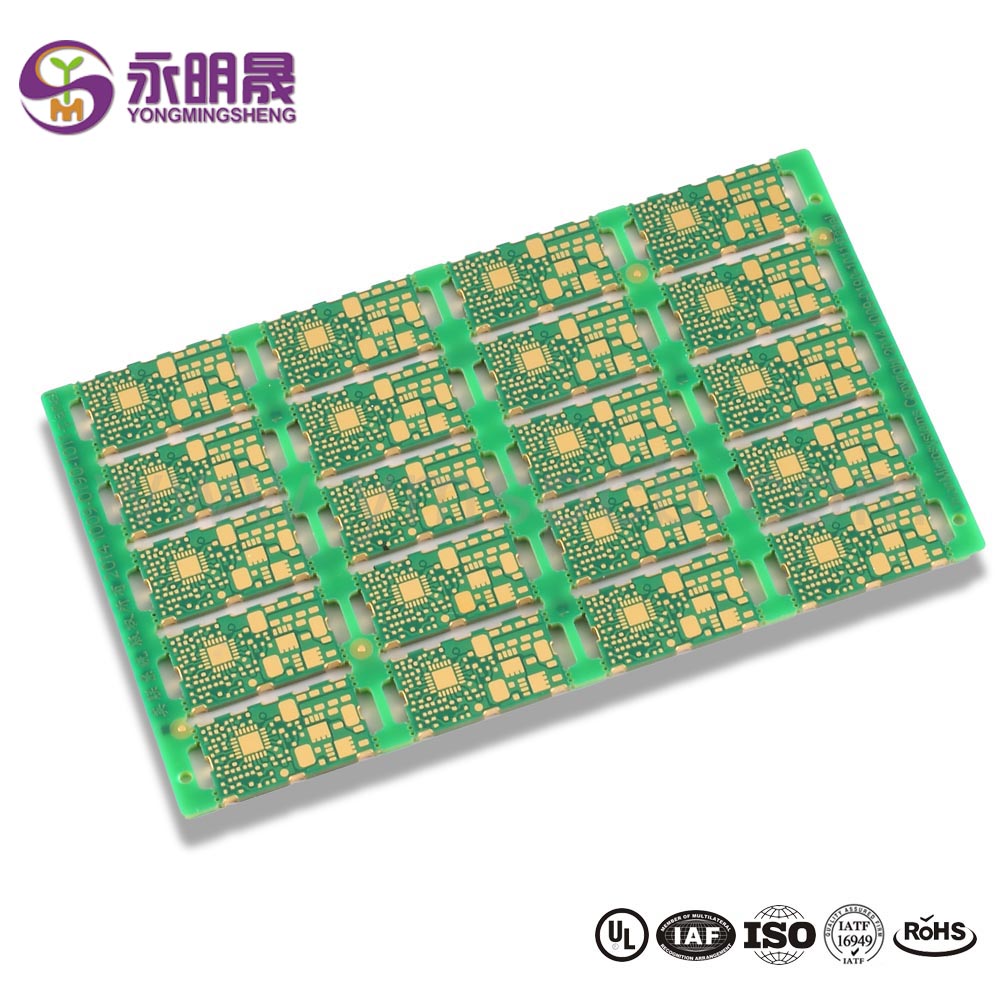

Double sided PCB material can vary on the basis of project type. However, the core material is almost the same for all circuit boards. However, the structure of the PCB varies from type to type.

Substrate: It is the most important material made of fiberglass. You can consider it as a skeleton of the PCB.

Copper Layer: It can be either foil or full copper coating. That’s why it depends on board type. The end result is the same whether you use foil or copper coating. Double sided circuit boards contain a conductive copper layer on both sides.

Solder Mask: It is a protective layer of polymer. So, it prevents copper from short-circuiting. You can consider it as the skin of the circuit board. Double sided PCB soldering is a very important step for durability.

Silkscreen: it is the final part of silkscreen. Although it doesn’t have any role in the functionality of the circuit board. Manufacturers use it to show part numbers. Part numbers are very important for testing purposes. In addition, you can print your company logos or other information in the form of text.

The Advantages and Disadvantages of Double Sided Circuit Boards

Here are some pro and cons of double-sided printed circuit boards:

Advantages of Double-sided Circuit Boards

High Quality: Planning and designing this PCB need a good amount of work. Resulting in high-quality circuit boards.

Enough Space for Components: It houses more space for components. Because both sides of the layer are conductive.

More Design Options: It has conductive layers on both sides. You can attach different electronic components on both sides. So you have more design options.

Sourcing and Sinking Current: While using it as a bottom layer, you can use it for sinking and sourcing current.

Usage: Due to its efficiency, you can use it in many applications.

Disadvantages of Double-sided Circuit boards

Higher Cost: Making both sides conductive, it comes at a slightly higher cost.

Skilled Designer Needed: There involves a bit difficult double sided PCB manufacturing process for its formation. Therefore, you need more proficient engineers for its productions.

Production Time: Production time is more than a single sided PCB due to its complexity.

Application of Double Sided Circuit Boards

This type of circuit board increases circuit density. They are more flexible as well. Almost all double sided PCB manufacturers use it in many electronic gadgets. Below is some remarkable use case of double-sided circuit boards:

HVAC and LED lighting

Traffic control system

Automotive dashboards

Control relays and Power conversion

Regulators and power supplies

To test and monitor different equipment

Printers and cellphone systems

Vending machines.

YMS Normal PCB manufacturing capabilities:

| YMS Normal PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-60L | |

| Available Normal PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 Mix etc. | |

| High Speed Material such as M7NE and FR4 Mix etc. | ||

| Material | CEM- | CEM-1;CEM-2;CEM-4;CEM-5.etc |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF,NP170G etc. | |

| High Speed | Megtron6, Megtron4, Megtron7,TU872SLK, FR408HR,N4000-13 Series,MW4000,MW2000,TU933 etc. | |

| High Frequency | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 etc. | |

| Others | Polyimide, Tk, LCP, BT, C-ply, Fradflex, Omega , ZBC2000,PEEK,PTFE,ceramic-based etc. | |

| Thickness | 0.3mm-8mm | |

| Max.copper Thickness | 10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

Video

Learn more about YMS products

Read more news

What is a double sided PCB?

Double Sided PCB or Double Layer Printed Circuit Board is little complex than Single Sided PCBs. These types of PCB have one single layer of the base substrate but conductive (copper) layer on both sides of the substrate. Solder mask is applied on both sides of the board.

What is double layer PCB used for?

Consumer Electronics;Industrial Electronics;Automotive Uses;Medical Devices

How is a double layer PCB made?

FR4+copper+soldermask+silkscreen

What is the difference between single layer and double layer PCB?

Single-sided PCB diagram mainly used Network Printing(Screen Printing), that is, resist on the copper surface, After etching, mark the welding resistance, and then finish the hole and the shape of the part by punching.

Single-sided printed circuit boards are widely used in many electronics, whereas double-sided circuit boards are often used in higher technology electronics.

Single-sided printed circuit boards are commonly used in an array of electronics and applications, including camera systems, printers, radio equipment, calculators, and much more.

Board21-300x300.jpg)