HDI printed circuit boards 8Layer 2 Step HDI Board| YMS PCB

HDIPCB is the high-density interconnector PCB. It is a type of PCB technology that is very popular in various devices. HDI PCBs are the results of miniaturization of components and semiconductor packages because they can realize more functions on the same or less board area through some technologies.

HDI PCBs have finer lines, minor holes, and higher density than conventional PCBs, providing necessary touting solutions for the chips with many pins in mobile devices and other high-tech products.HDI PCB usually has 4,6,8 layer or even higher.

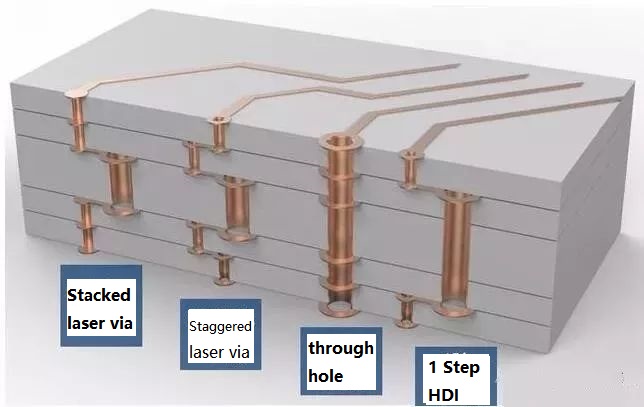

HDI design combines dense component placement and finer circuits, using less board without compromise functions. Compared to ordinary PCBs, the main difference is that HDI PCBs realize the interconnect through blind vias and buried vias instead of through holes. And HDI PCBs use laser drilling while traditional PCBs usually use mechanical drilling. The birth of the HDI PCBs brings more possibilities for portable electronic devices and more challenges for PCB manufacturers. For accommodating the trend of miniaturization and multifunction of electronics, YMS has done a lot to improve the level of equipment and staff professionalism. You can be assured to offer us the HDI designs, and we will give you a satisfactory service and HDI products.

HDI基板製造プロセス:

At present, HDI board interconnection between layer and layer is mainly the following design: Staggered holes interconnection, Cross-layer interconnection, ladder interconnection and superposition holes interconnection. Among them, the superposition holes interconnection occupy the least space. There is a research suggests that reducing the number of through holes and increasing the number of blind holes can effectively improve the wiring density. And in the superposition interconnection, the methods of electroplating and resin plug are mainly used, especially the electroplating hole filling method which has more obvious advantages like high reliability and good conduction performance. Therefore, superposition interconnection is the most widely used design method for blind holes design. The process of stacking between layers is as follows: first blind hole is made, then second blind hole is made after lamination, then multi-blind hole is made according to this method, and the interconnection between layers is realized by electroplating hole filling method.

全体的に、HDIプレートの製造方法は、長い時間のために生産の何倍もの後に完了する必要がある、複雑です。 それだけでなく、それぞれの層の精度と収縮制御のための高い要求するだけでなく、材料、設備、環境、技術者では高い水準です。

YMS HDI PCB manufacturing capabilities:

| YMS HDIPCB製造機能の概要 | |

| 特徴 | 機能 |

| レイヤー数 | 4-60L |

| 利用可能なHDIPCBテクノロジー | 1 + N + 1 |

| 2 + N + 2 | |

| 3 + N + 3 | |

| 4 + N + 4 | |

| 5 + N + 5 | |

| 任意のレイヤー | |

| 厚さ | 0.3mm-6mm |

| 最小線幅とスペース | 0.05mm / 0.05mm(2mil / 2mil) |

| BGAピッチ | 0.35mm |

| 最小レーザードリルサイズ | 0.075mm(3nil) |

| 最小機械ドリルサイズ | 0.15mm(6mil) |

| レーザー穴のアスペクト比 | 0.9:1 |

| スルーホールのアスペクト比 | 16:1 |

| 表面仕上げ | HASL、鉛フリーHASL、ENIG、イマージョンスズ、OSP、イマージョンシルバー、ゴールドフィンガー、電気めっきハードゴールド、選択的OSP、ENEPIGなど。 |

| 塗りつぶしオプション経由 | ビアはメッキされ、導電性または非導電性エポキシのいずれかで満たされ、次にキャップされ、メッキされます |

| 銅充填、銀充填 | |

| 銅メッキによるレーザーシャット | |

| 登録 | ±4mil |

| 戦士の表情 | 緑、赤、黄、青、白、黒、紫、マットブラック、マットグリーンなど。 |

What is HDI material?

FR4 Fiberglass board or ceramic board

Are printed circuit boards still used?

Yes,the Printed circuit board(PCB) is the foundation of electronic equipment, and it can be found in every electronic device in today ’s world

What is the major disadvantage of printed circuit boards?

1.single use 2.environmental pollution 3.high cost

Is there gold in printed circuit boards?

yes,there is